LED street light design is a completely different challenge to traditional discharge lighting. This article discusses an important consideration in the form of maintanance factors. Although LED's promise exceptional life cycles - what happens when you put them in the public realm in difficult environments?

Traditional Methodology

When designing with discharge lighting the concept of maintenance factors is well understood and documented. Once a cleaning regime for the proposed scheme has been determined then the appropriate luminaire maintenance factor can be determined from tables in the British Standard.

For example, in the soon to be published Draft BS 5489-1 2012, figures of 0.88 and 0.84 are given for IP65 or greater luminaires at 6m or less in an E3 or E4 zone for a four year and six year cleaning cycle.

These figures are published for luminaires of IP65 or greater and, as no appreciable dirt will enter these optics, the figures therefore relate to the dirt build up on the outside of a luminaire which obscures the light leaving the optic.

The figure selected is then multiplied by the lamp lumen depreciation figure for the same time period which is obtained from the lamp manufacturer’s lumen depreciation curve. The resulting figure gives the maintenance factor to be used for the scheme design.

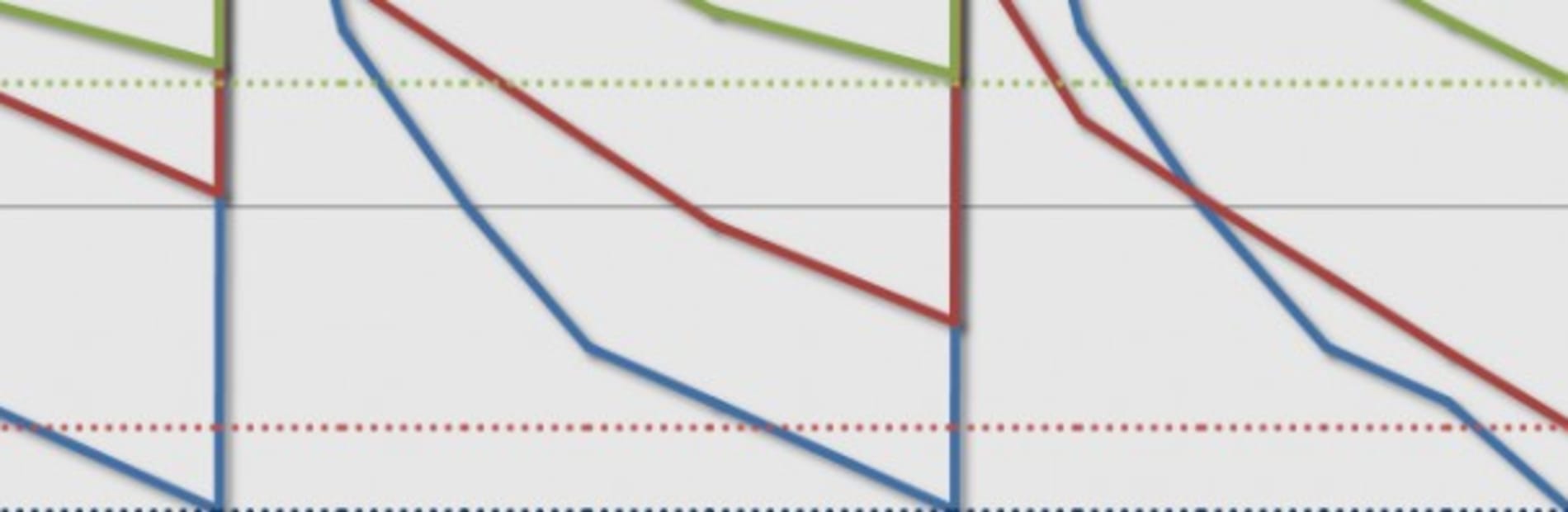

When the lamp is replaced and the exterior surface of the optic cleaned then the light output of the luminaire will theoretically return to its initial value of 100%. If the light output of the luminaire was plotted against time then the light output would be as per the blue line as shown on figure 1.

Figure 1

Shows depreciation of overall light output over time taking into account both dirt build-up on the luminaire and the reduction in output of the lamp over time. Design level lines show the level the scheme must be designed to.

The lighting level on the ground will always be above the design lighting level and only reach the design level during the nights before the luminaire is cleaned. Consequently the scheme is always over-lit (see figure 1a), and only approaches its design level every four years.This represents a large amount of wasted energy.

Figure 1a

Shows wasted energy due to over lighting.

The Challenge of LED Light Design

When we design with LED luminaires we are faced with a challenge. Assuming that the LED luminaire is sealed to the same degree i.e. IP65 or greater, then the same luminaire maintenance factor will be applicable.

However, the LEDs are not replaced at cleaning and if the quoted lifetimes of 50 to 60,000 hours are reached then it will be 15 years or more before the LED modules, or indeed the whole luminaire, are replaced.

LEDs in general do not fail suddenly as we are used to with discharge lamps, the light output of an LED gradually reduces over time. The L70 figure is commonly quoted for LEDs as the life in hours as to when an LED will reach 70% of its initial brightness. If this figure of 0.7 is used as the source lumen maintenance figure, and then multiplied by the luminaire maintenance factor, then we end up with a design maintenance figure of 0.58 for a six year cleaning cycle.

Plotting the output of the light source solely we get a graph as shown in figure 2 (below.) This is in contrast to the graphs plotted above, which are inclusive of the cleaning regime.

Figure 2:

Shows reduction in output of the lamp over time. Blue line shows drop in output for a discharge lamp, which gets changed every 5-6 years.

LED power supplies are now being developed that compensate for this. They slowly ramp up the power supplied to the LEDs over the predicted lifetime. This helps to compensate for the gradual lumen depreciation over time and can lead to much improved lumen maintenance figures. Additionally, as the LED is effectively dimmed on initial start they are not stressed to perform at 100% and the diode will last longer as a result.

The rate of lumen depreciation of LEDs is very dependent upon junction temperatures. To keep this depreciation to a minimum, the junction temperatures should be kept as low as possible. By minimising the junction temperature, the lumen depreciation curve will be almost flat and the minimum amount of light and energy will be wasted. Figure 2 shows this as real life figures from discharge lamp vs an LED with a low junction temperature.

Here are our calculations for reference, please note they are generic LED projections and not specific to Marshalls components or luminaires:

LED Street Light Design - Maintenance Factors - Calculations