Blog

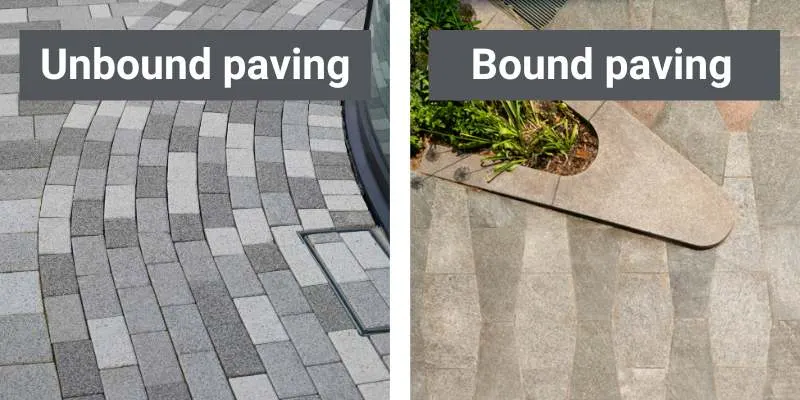

Unbound modular paving is one of the most well-established and widely used pavement materials. It is a type of paving system that uses interlocking concrete, clay or stone paving modules that are set in a bed of gravel or sand. The paving units aren’t bonded together, so they can flex and move slightly, allowing a pavement or access road to withstand trafficking and loading.

The unbound method of modular pavement installation relies on creating a frictional interlock between adjacent paving units to resist the turning and braking forces applied by vehicles and other traffic, which is why the bond pattern the paving is laid is important for the integrity of the pavement.

Advantages aside, there are some misconceptions about aesthetic limitations with unbound modular paving. In this blog, I’ll outline the benefits and drawbacks of this style of pavement design to help you specify your next project with confidence.

Bound vs unbound pavements: What’s the difference?

Pros of unbound modular pavements

Low-cost

Unbound paving uses sands and aggregates as jointing, laying course and subbase, which is a cheaper alternative to bound materials such as mortars or concretes.

Easy maintenance access

It is far easier to access services below an unbound modular pavement. You can simply lift and reinstate the paving used, where a bound pavement would need to be removed and likely not recycled.

Speed of installation

It is quicker to install an unbound modular pavement (compared with bound stone setts, for example), and the pavement can be opened to pedestrian traffic immediately. There is no waiting for cementitious materials to cure and gain adequate strength, making it an attractive solution for busier city-centre locations.

Ease of installation

Laying all types of paving requires skill and training, but some installations are far easier than others. Installing unbound modular paving is more straightforward than bound paving, with smaller margins for error thanks to uniform dimensions and handy spacing nibs.

Heavy traffic applications

Contrary to belief, unbound modular paving can withstand heavy traffic, but this can be subject to the size of the block used and the laying pattern. This example at Felixstowe port used a small block paved surface in a herringbone bond pattern and has been able to withstand the heavy traffic demand at this port.

More sustainable

Materials used for unbound modular pavements, such as sand and Type 1 aggregate, have smaller quantities of embodied carbon compared to the mortars and high-strength concretes used for bound pavements. If environmental credentials and responsibilities are a top priority, opting for unbound paving might be the favourable solution.

Cons of unbound modular pavements

Sand joint maintenance

With an unbound modular pavement using sand joints (normally fine and kiln-dried), there is some risk/potential that this sand will be removed, often when mechanical sweepers are used during the months following the installation. It’s important to note that the sand joint is a critical component within a pavement’s construction, creating the frictional interlock that the pavement requires to resist trafficking forces.

The sand joint also prevents the paving units from coming into direct contact with one another, which will result in chipping, spalling and damage to the paving units. If you opt for an unbound modular pavement, it is necessary to regularly inspect and top-up jointing sand to keep the pavement looking and functioning at its best.

Material limitations

As we’ve already learnt, unbound modular pavements rely on sand jointing. But they also require a frictional interlock created by the sand jointing and rough texture of the paving units in order for them to withstand trafficking forces.

Not all paving materials have enough texture to their sides to create this level of interlock. One example of this is sawn granite, which lacks friction/roughness on its sides, as is shown in the image below.

[Sawn granite unbound pavement installation caused chips and loose units because of no friction from the side of the blocks and loss of sand.]

Laying and bond pattern limitations

As well as being slightly limited in terms of material choice, an unbound construction can also be limited when it comes to the bond patterns that can be used in trafficked applications. A herringbone bond, for example, is excellent at resisting the turning and braking forces from heavy vehicles and other traffic.

However, stretcher bonds, running bonds, basket-weave and stack bonds don’t create enough interlock between adjacent units to resist rotational forces applied by frequent heavy vehicles. These types of unbound laying patterns are only suitable for lightly trafficked or pedestrian-only applications.

Paving unit size limitations

Small paving units, such as concrete block paving, can act under compression. When loads and trafficking are applied to small units, these forces work to try to crush and rotate them, which these units can resist in a flexible, unbound construction.

With larger units, such as slabs and flags, these act under tension when loads and trafficking are applied, which makes them want to bend and snap. Larger units aren’t always suitable for an unbound pavement installation method, as it relies on being able to flex under loadings, though there are limited exceptions.

Myths about unbound modular pavements

- All unbound modular paving slabs are permeable

- Unbound pavements are always cheaper

- Bound pavements last longer than unbound pavements

Final thoughts and further help

Unbound modular pavements are a great, low-cost, often lower-carbon and time-efficient method of installing a paved surface that can accommodate heavy trafficking, but they have their limits and restrictions when it comes to ongoing maintenance and aesthetics.

Marshalls has a wide range of paving products suitable for all applications and an experienced, dedicated in-house design and engineering team to support you in selecting the best products and the best methods of installation to enable you to achieve your ambitions with any hard landscaping project.

For more information on how we can help, please contact us at design.team@marshalls.co.uk.

If you want to learn more about pavement engineering, explore our CPD modules.